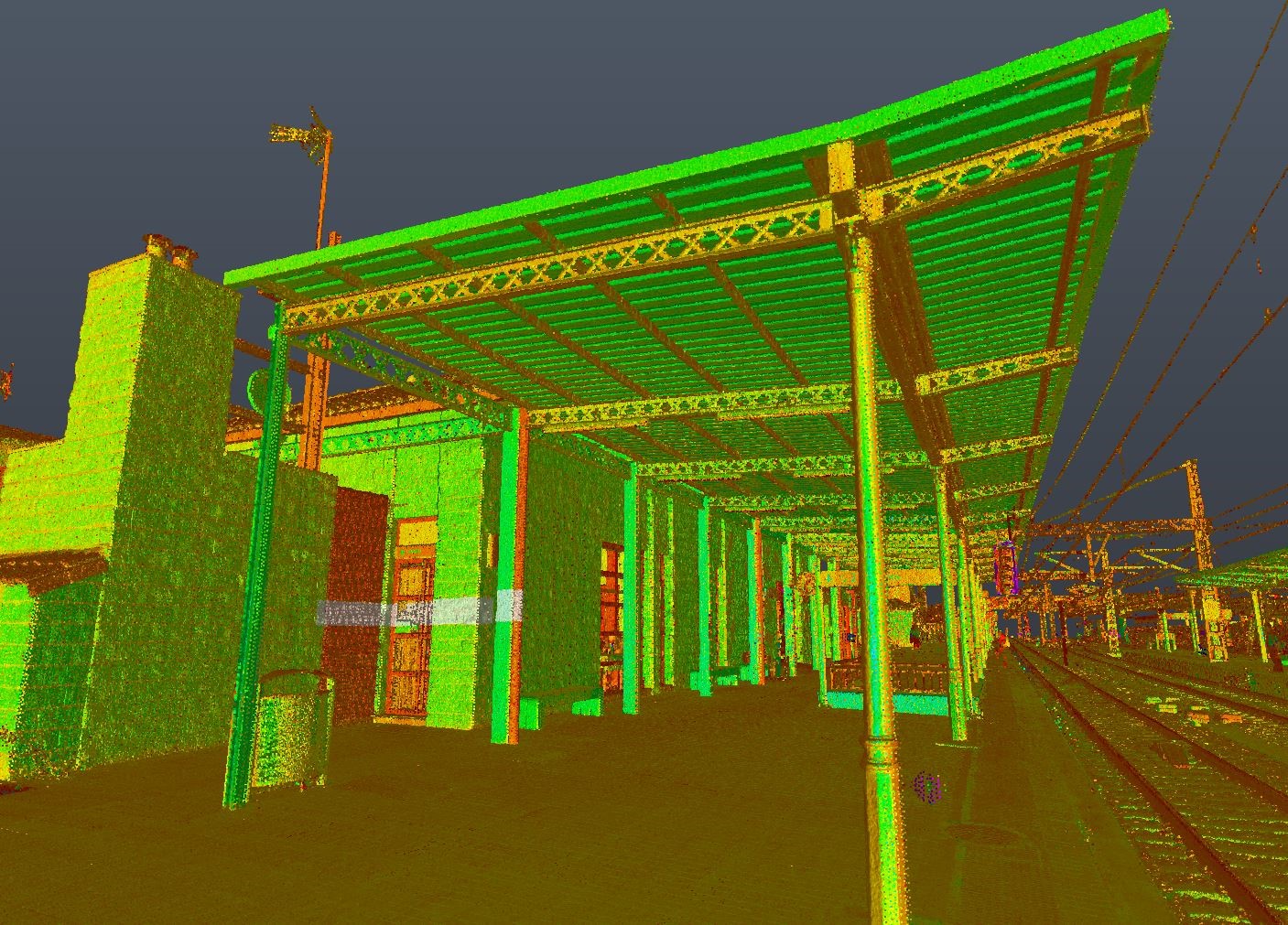

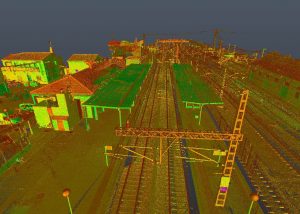

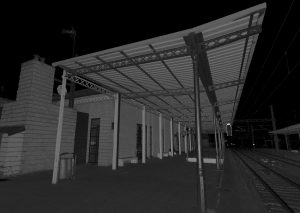

Laser scanner technology offers high accuracy in measuring objects or surfaces located within a limited radius. It offers the opportunity to be able to transfer any object or terrain to a plan or model, with high precision. Laser scanner devices work by using laser waves that calculate the varying lengths of nearby objects, which can be observed on the scanned surface.

Initially, it is based on a detailed study of the type of work and its needs, the characteristics and dimensions are two fundamental factors to be able to prepare and calculate the field work properly.

Planning in the use of laser scanners is essential to improve productivity and work efficiency. At Nova Cartografía we have different types of laser scanners, and we evaluate which one is optimal for each project.

- Optimal equipment and instruments

- No. of scans and position

- Time Spent Estimation

- Georeferencing coordinates

When collecting data, we select the resolution according to the ambient light intensity and the desired quality. We position targets, support targets that will serve as a reference to unify the different scans with higher precision. The laser scanner measures millions of points with high precision and in a short period of time. Sometimes you will need to make different captures from different stations or positions to ensure complete coverage.

The methodology followed by the use of laser scanners serves to collect information in the area of intervention, allowing important information to be seen between the points.

To talk about laser technology is to talk about millimetric precision. This quality guarantees its corresponding calibration:

-Point cloud in open format: they will provide the necessary information to later process the data.

-Delineation required at each step: with great precision it will allow the client in future consultations to access to be able to make new modifications in the project/work.

The objectives to be developed in a laser scanner job are based on anticipating conflicts, being an easy way to save on execution costs. The intervention has to be analysed using real models of alternatives, ensuring a survey of plans with high millimetric precision. The distinction in a high-precision technological service gives confidence to your customers and ensures greater efficiency in the service. The potential of the object allows the real object to be transformed into a virtual one and to be able to make certain changes to it by manipulating it until the desired result is obtained.

In the laser scanner there are two types of sensors, short and long range, depending on the size of the type of object; it is the scanner itself that calculates the distance from the object using its laser light beam.

The performance of the station helps to obtain measurements with the required accuracy, evaluating workflows and not just the speed of points per second. Reconnaissance of the intervention area to collect information is essential to be able to organize the necessary sweeps of the surface to be analyzed.

Published by: admin in Noticias

Comments are closed.